STUTTGART, GERMANY – A van that guides a drone, a robot that delivers your parcel: these may sound like futuristic dreams, but Mercedes-Benz says it’s surprisingly close to making them reality.

And while many vehicle makers rely on third-party companies to design and sell aftermarket systems to customers, this German automaker plans to be the one providing them.

While it’s best-known here for cars and SUVs, Mercedes-Benz is a huge name in work trucks in many global markets. It currently only sells its Sprinter and Metris vans in Canada, but in other markets it’s equally well-known for buses and trucks as well.

That focus is important, because while consumer technology is an important selling point, there’s an even bigger world out there for commercial applications. Some automakers have delved into it, such as the telematics that Ford offers to fleet buyers, but Mercedes-Benz plans to make it a cornerstone of its commercial business.

It’s a strategic initiative called adVANce, and it covers a wide range of applications. In North America, it could potentially push the company ahead in a segment it once all but owned – its Sprinter was the first European-style van to reach our shores – but where it’s now being challenged by competitors such as Ford’s Transit, which offers similar capability but is represented by a larger dealer network.

Overall, the general idea isn’t new, since virtually every automaker offers third-party technologies. But unlike consumer items that buyers use during the trial period but might not renew, such as satellite radio or OnStar, these commercial applications should prove irresistible to companies looking to improve productivity.

Some are being developed in conjunction with outside companies, many of them start-ups. Others are in-house, created at the automaker’s “innovation studios” in Stuttgart, Berlin, and Silicon Valley, staffed by young engineers and designers in free-flowing, unstructured environments.

So what might you possibly expect to see in the future? Here are some of the ideas presented.

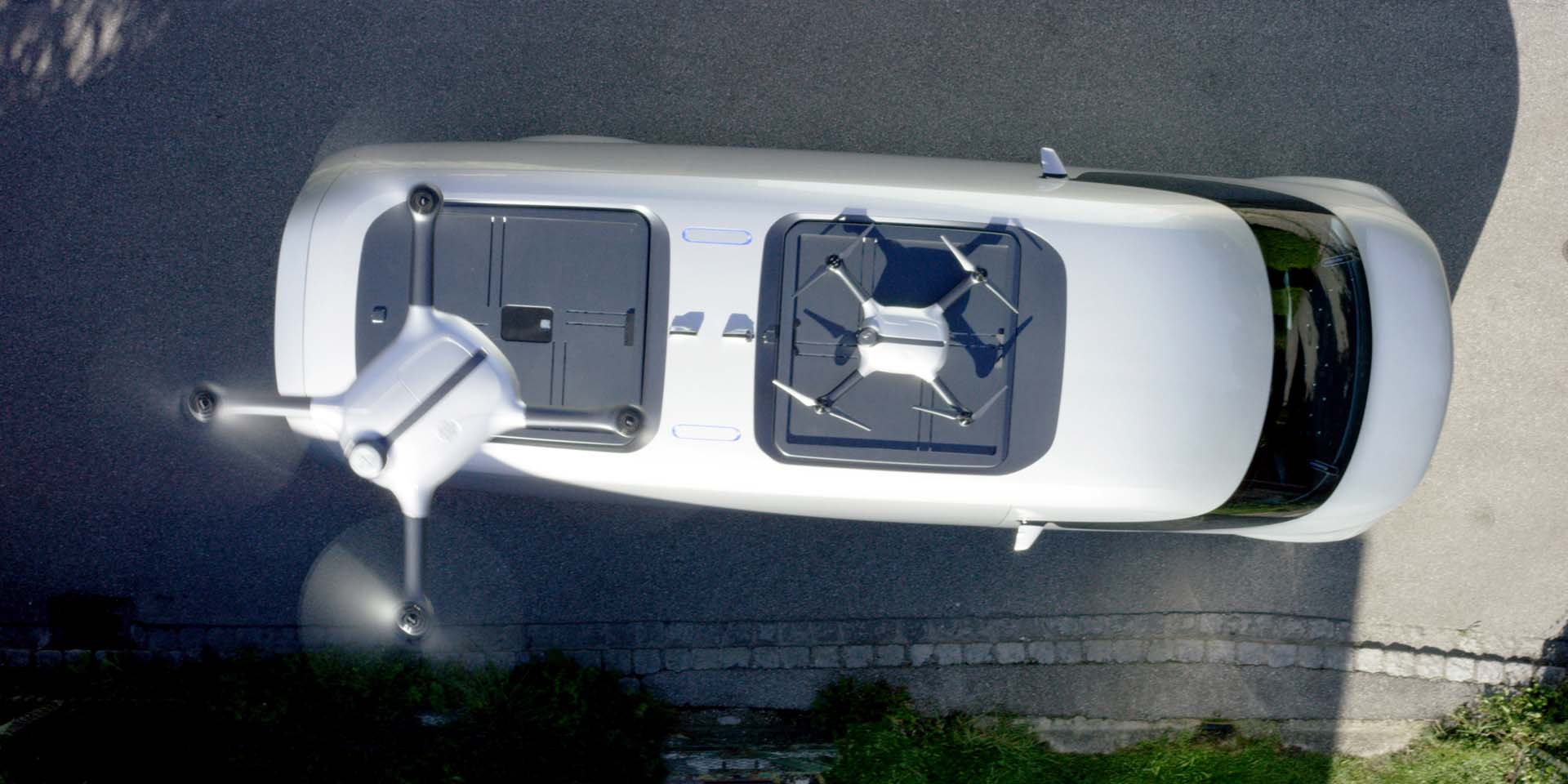

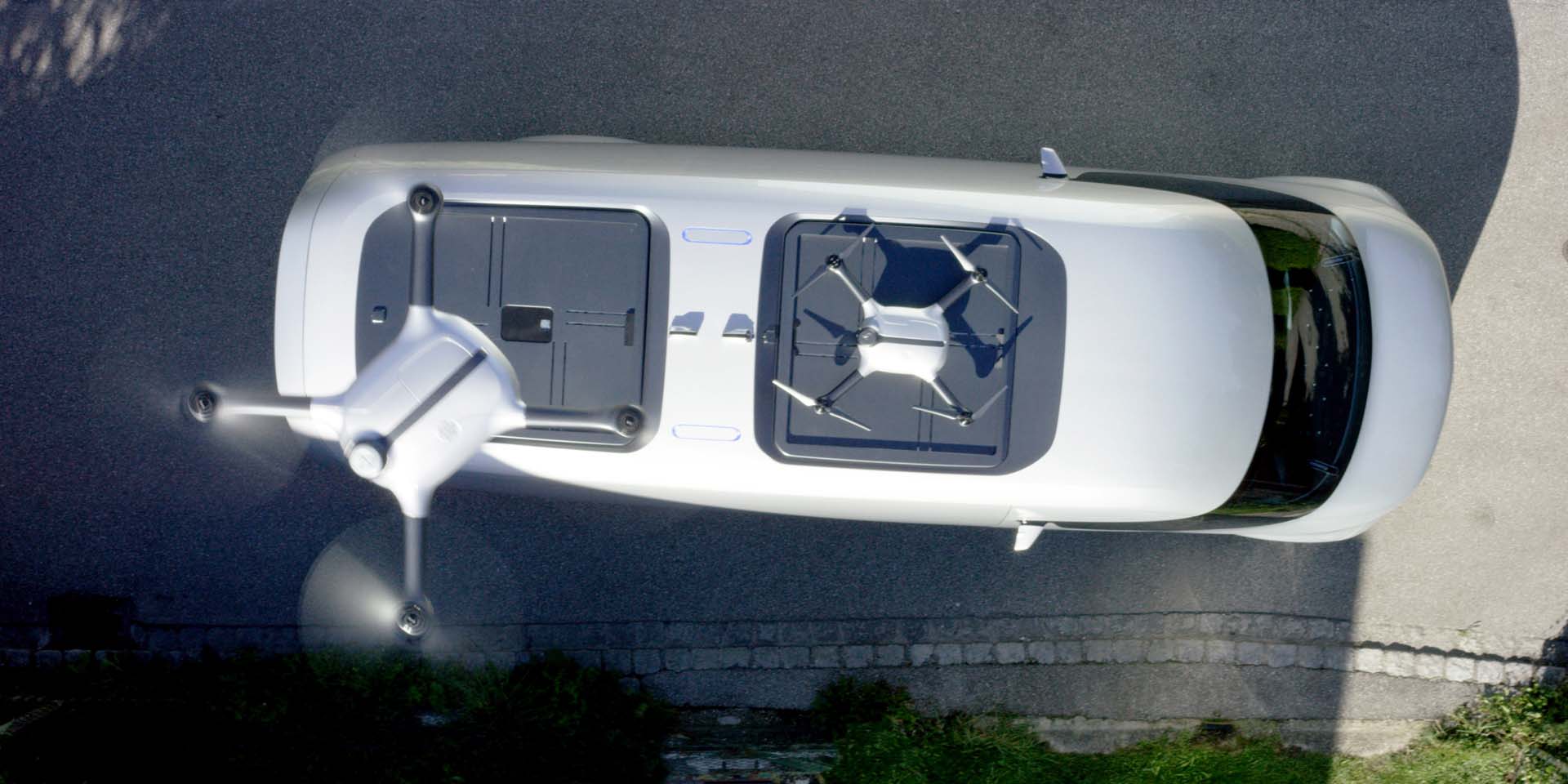

Drone Delivery

Sure, you’ve heard about it from Amazon, but this one has a “work twist”. If someone on a construction site discovers he’s out of small items or has broken a tool, he hooks up with his supplier through a cellphone app and places an order. The supplier packs the order onto a drone, which makes its way to the job site guided by a beacon in the worker’s Metris van. After receiving a go-ahead from the worker through the app, the drone lands on the van’s roof, drops the parcel, and returns to the supplier. The system was developed with drone start-up Matternet.

Robot Delivery

A project in conjunction with Starship Technologies sends a Sprinter equipped with robots to a central area, with the robots making the final delivery of small parcels.

A project in conjunction with Starship Technologies sends a Sprinter equipped with robots to a central area, with the robots making the final delivery of small parcels.

Created with Starship Technologies, this uses a Sprinter “mothership” outfitted with battery-powered robots.

The van is loaded with parcels and driven to a central location. The driver packs each robot with its parcel, and they take off along the sidewalk at about 6 km/h, with a range of up to three kilometres. They’re able to detect and avoid obstacles, and they’re equipped with cameras so that, if necessary, a dispatcher can see what’s in front of them as well. When the robot arrives at the destination, a message goes out to the recipient, who uses an app to unlock the robot and retrieve the parcel.

While all this is happening, empty robots from previous deliveries sense the arrival of the “mothership” and start making their way toward it. Once they arrive, they’re loaded up and taken back to the warehouse for restocking. The company is also working on an autonomous system inside the van that will load packages in the robots, so the operator’s sole task will just be to drive.

Materials Delivery

Rather than head to a hardware store to stock up on screws and bolts, a tradesperson scans the empty parts boxes in the van. The code on each box corresponds to a supplier’s app that shows the type and size of fasteners in each. The tradesperson then enters the quantity of each one required, and goes home at the end of the day.

Meanwhile, the supplier picks and packs the materials, and sends them out for delivery. The delivery driver goes to the tradesperson’s van, remotely unlocks it with an app, puts the parcel inside, and remotely locks it back up. In the morning, the tradesperson opens the package and restocks the van.

Cargo Sensing

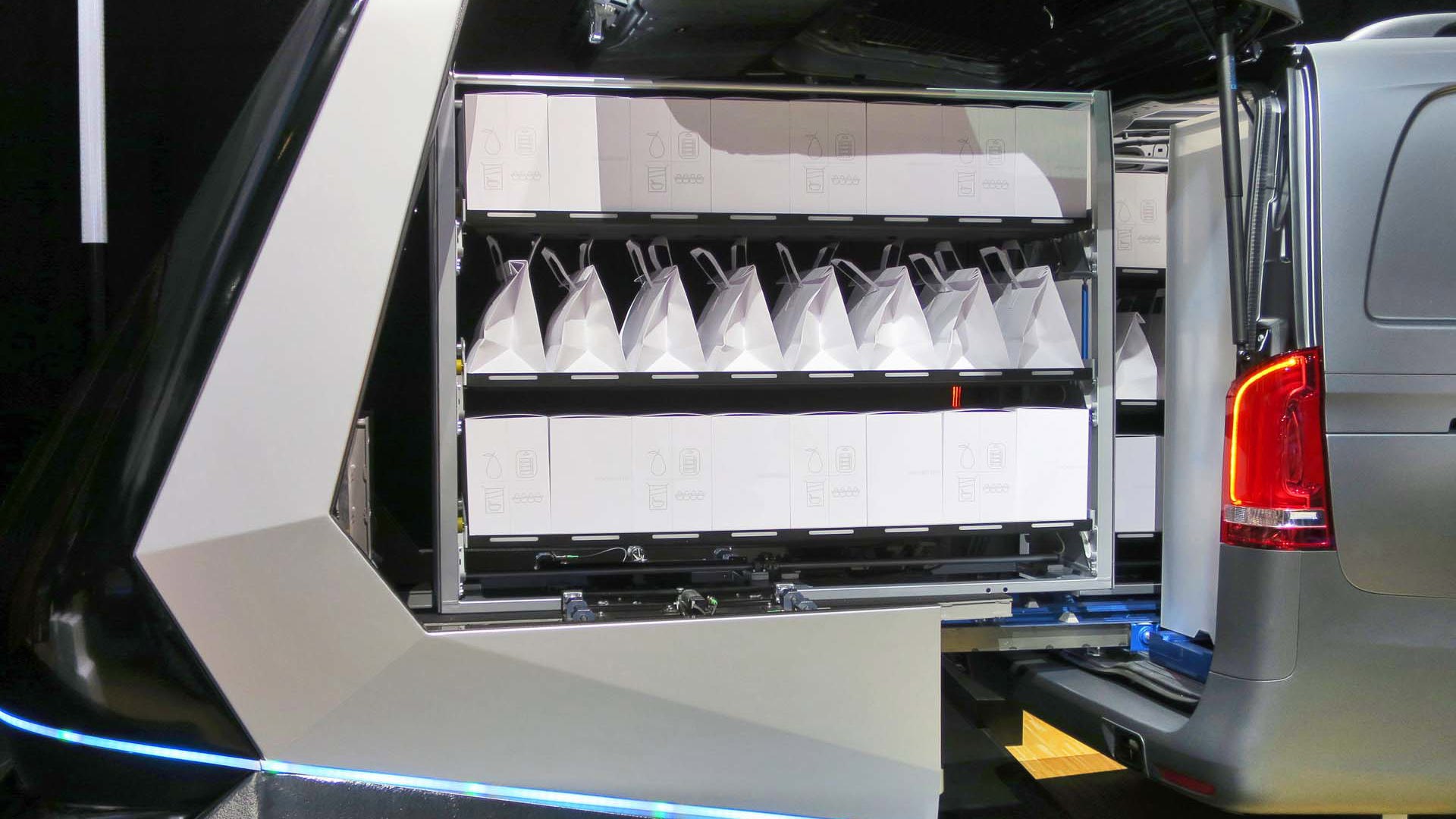

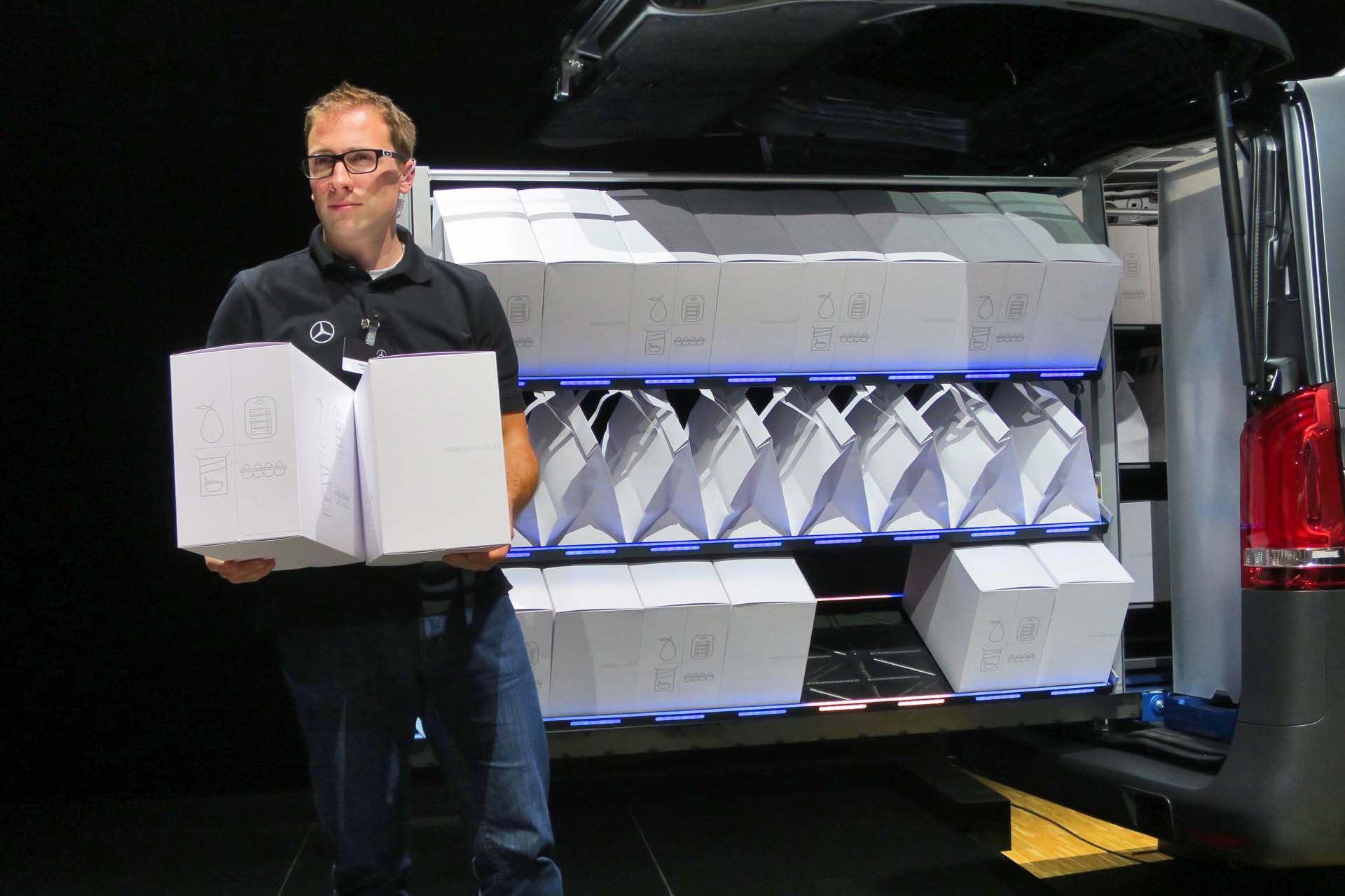

A concept "Slider" system puts pre-loaded shelves into a van, eliminating any wasted empty space inside the van. Lights below the parcels tell the driver which pieces are dropped off at each destination.

A concept "Slider" system puts pre-loaded shelves into a van, eliminating any wasted empty space inside the van. Lights below the parcels tell the driver which pieces are dropped off at each destination.

Called a “pick-to-light” system, this identifies parcels as they’re packed into shelves on the van. Even though the driver loads them in no particular order, the system’s software identifies them and matches them to delivery information already in its memory. When the driver gets to each destination, a light illuminates under the matching parcel, eliminating the need to search through the parcels and look at the address on each one.

Cargo Slider

Inside most delivery vans, parcels either get stacked on the floor or on shelves with an aisle in between for the driver to access them. Both methods waste valuable space.

This system, developed in-house by Mercedes-Benz, starts inside the warehouse where workers load parcels into shelving units. These go into an automated robot that whisks them out to the van and slides them in, completely filling the cargo space. Each parcel’s position is tied into software that determines the van’s location by GPS. When the driver arrives at a delivery address, the system automatically slides out the correct shelf and then lights up to show which parcel is to be delivered.

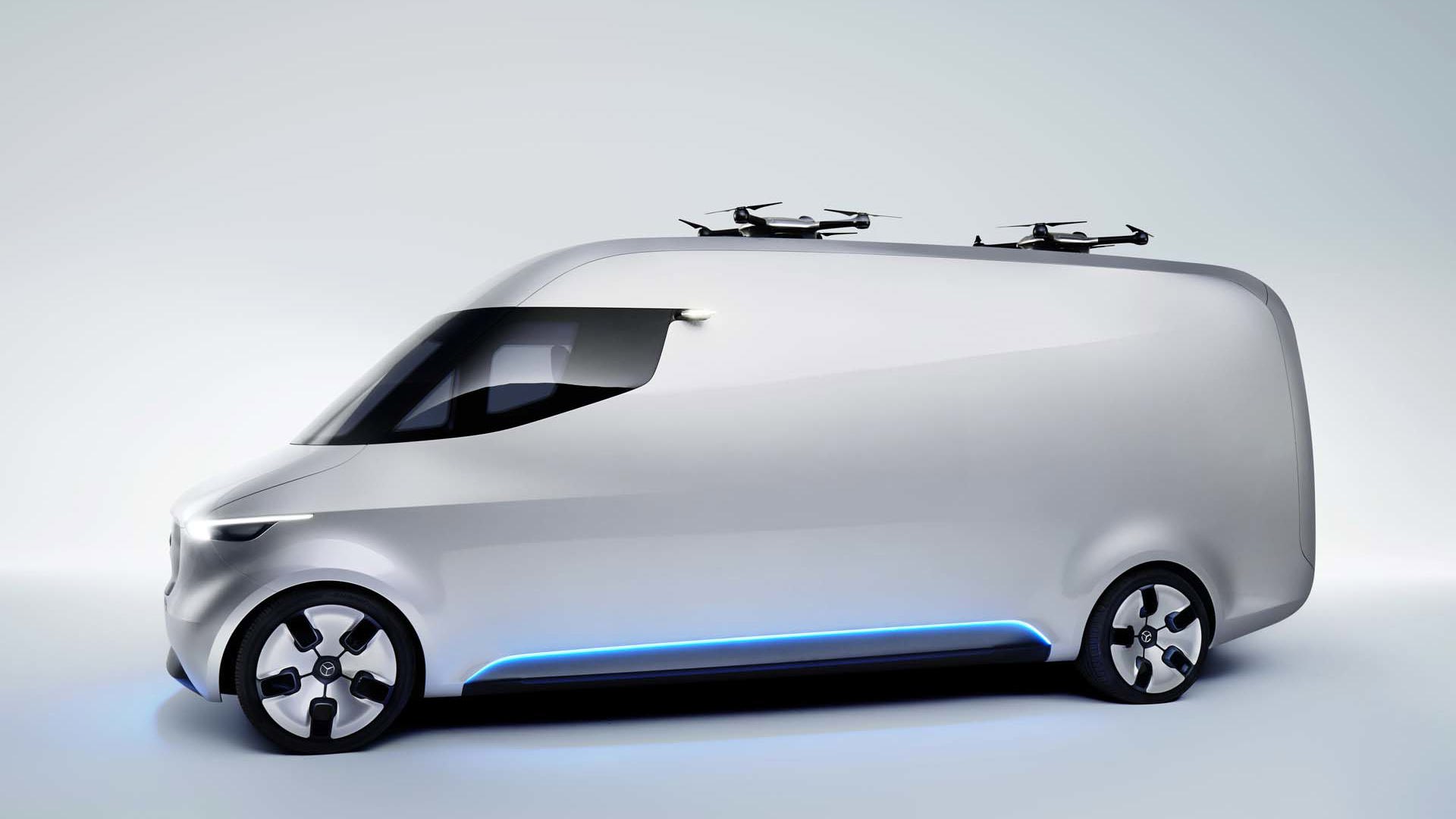

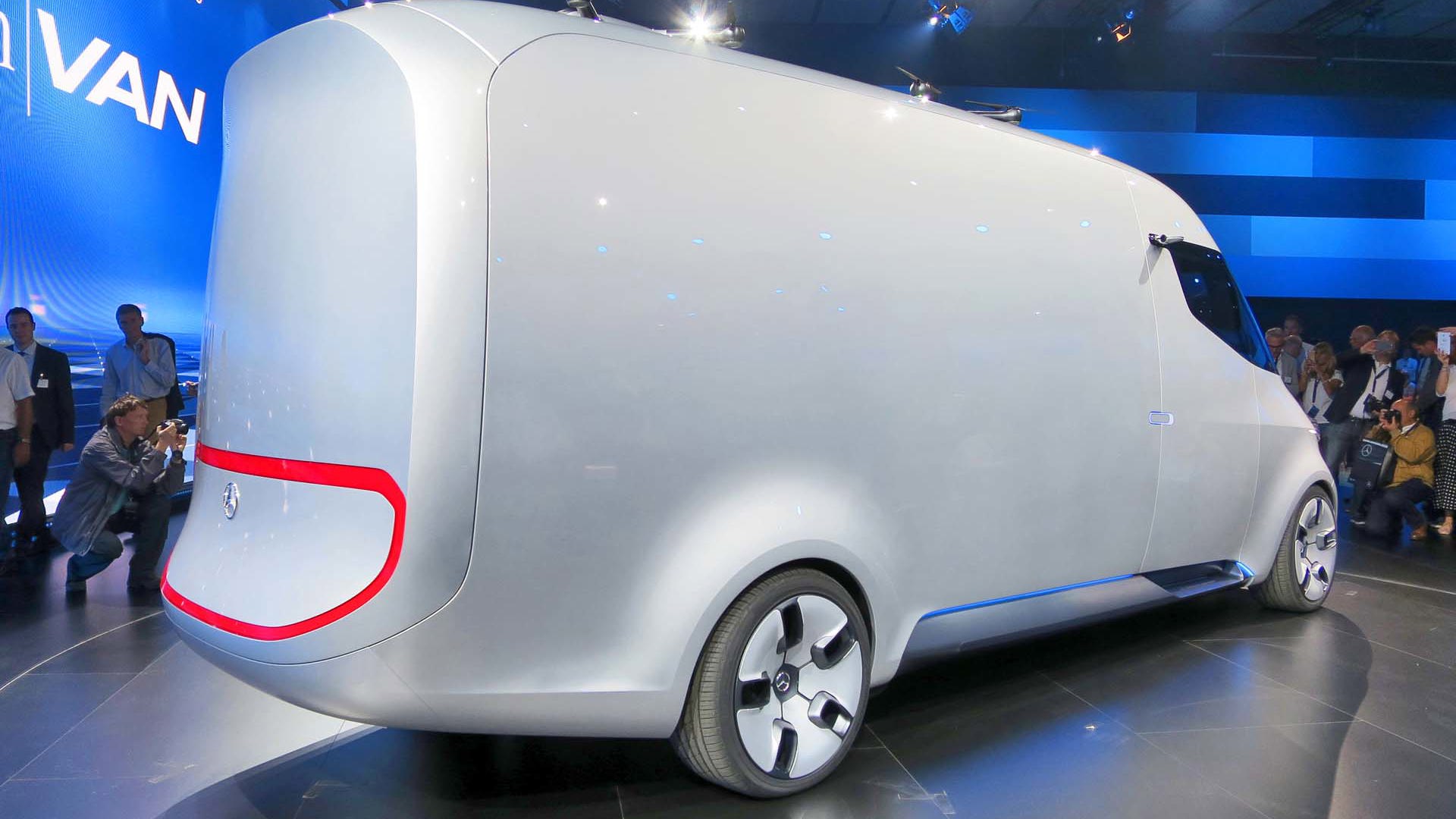

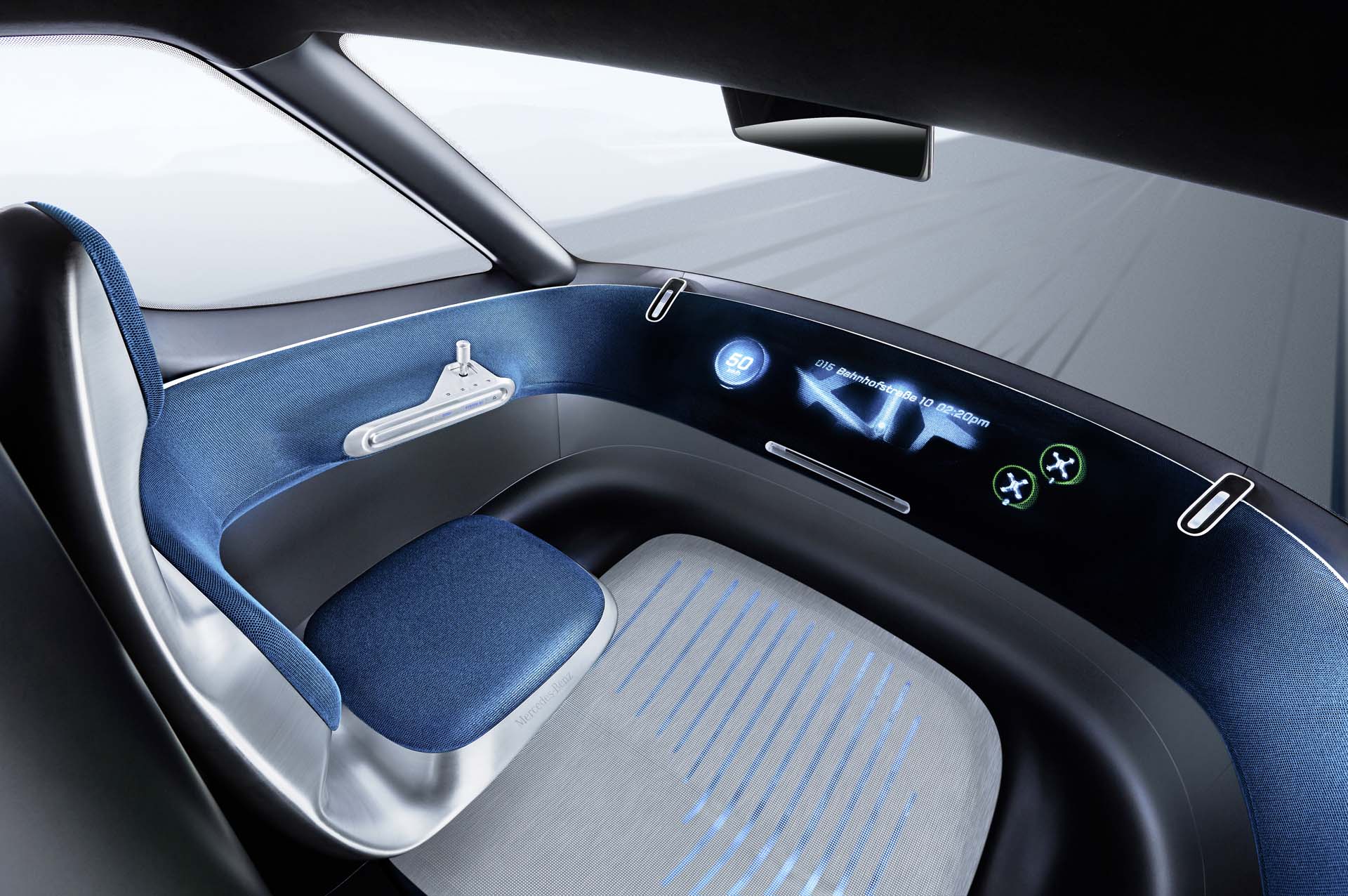

Vision Van Concept

At the event, Mercedes-Benz also presented the world premiere of its Vision Van concept. It’s not exactly a pretty vehicle, but it’s packed with technologies that could find their way into vans of the future, including an electric driveline, joystick operation, virtual dashboard, automated packing system, and drone delivery.

But beyond all of that, what might be the sea change here isn’t the technology itself, but how it will be sold. Up until now, automakers have made – well, autos. By offering the technology itself as part of a complete package, Mercedes-Benz may well have started a trend that could ultimately change car manufacturers into full service providers.