PUEBLA, Mexico – In a city of three million, a couple hours’ drive from the megalopolis that is Mexico City, sits a factory that finds itself the pivot point between Volkswagen’s past and its future.

The Puebla plant is perhaps most famous for its part in perpetuating the existence of one of the automotive world’s most enduring designs, the original Beetle, which was produced for export in the mid-50s and hung on until 2003 when the last Clasico rolled off the line. Today, on the eve of Día de Muertos, the most important holiday on the Mexican calendar, I am visiting the same facility as it says goodbye once again to the Beetle and hello to a very different tomorrow.

Past and Present

It’s an entirely appropriate timing for my Puebla plant rendezvous. Día de Muertos, or “Day of the Dead”, is a celebration of those who have passed on to the spirit realm, and a chance to carouse, feast, and dance with their memory when the other side of the ectoplasmic membrane pulls close to our flesh-and-blood world for a magical 48 hours.

The current Volkswagen Beetle, reanimated from its original death sentence, now hovers close to a second expiration, waiting only for its cue to shuffle off this mortal coil. That signal has come in the form of the Wolfsburg Edition, a send-off for the 2019 model year that will serve as the curtain call for the final generation of Beetle to grace Canadian showrooms.

Sibling Rivalry

That the birthplace of the most modern Beetle should also serve as the kick-off to a commemoration of its impending death feels a little like the universe shaking hands with itself.

In the distant shadow of a pair of the country’s stratovolcanoes, Volkswagen has constructed a sprawling complex charged with churning out exactly as many Jettas, Golfs, Beetles, and Tiguans as it can sell – and not a unit more.

It’s that last point wherein lies the tension that has spelled out the Beetle’s demise. Facing surging demand for its Tiguan sport-utility, and merely steady, if quite modest orders for the retro-themed coupe and convertible pairing, VW has made the choice to devote the space, resources, and expertise involved in Beetle construction to its family-oriented usurper.

Yet on this final day of October, the two live harmoniously side-by-side, each basking in the attention lavished upon them by the nearly 14,000 employees (with two-thirds of that number on the factory floor itself) under Volkswagen’s roof.

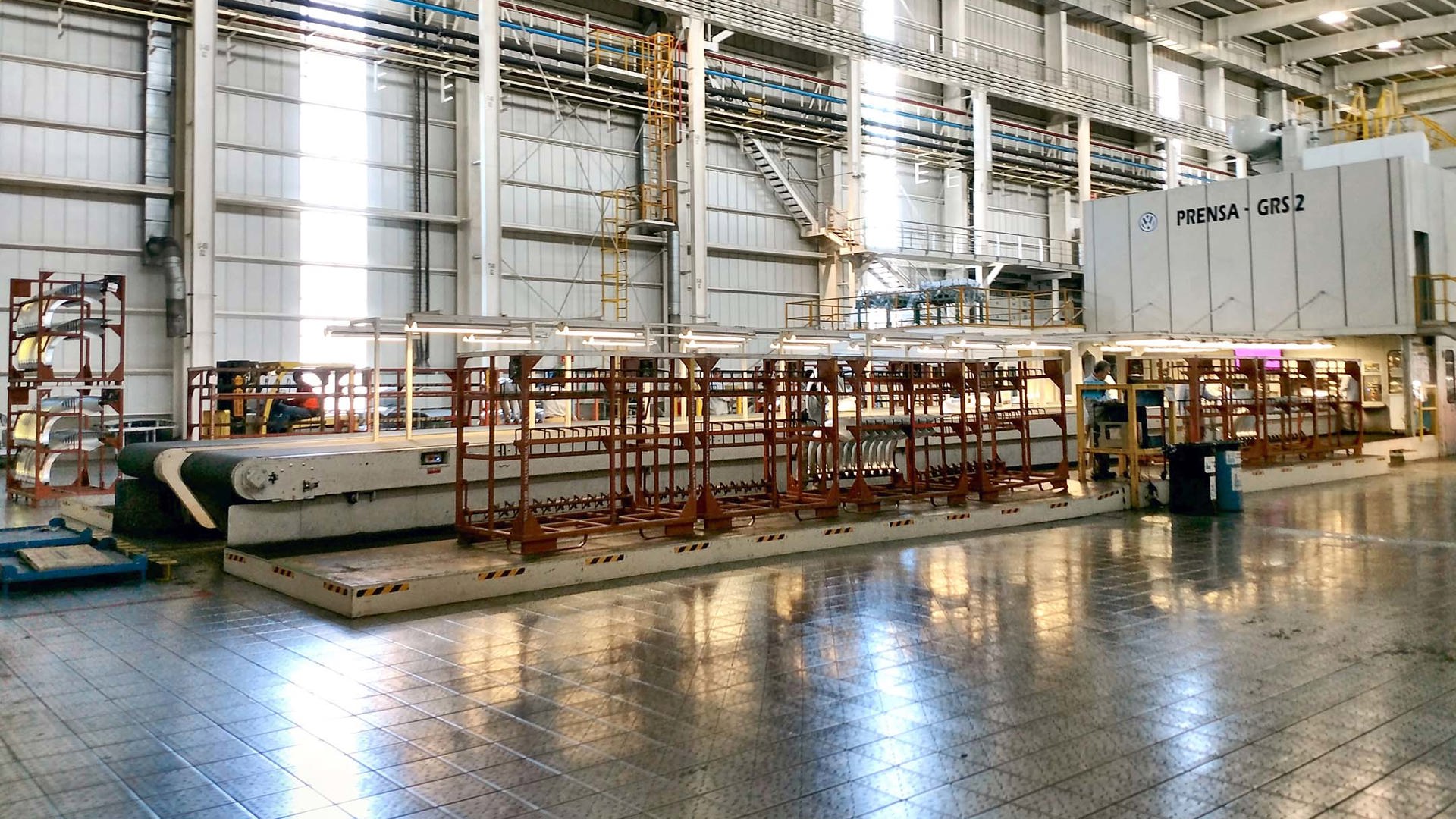

The plant itself is a wonder of modern engineering, as most production facilities of this size tend to be. Surrounded by lagoons, fed by rainwater and canals, as many as 2,300 vehicles a day are assembled here, of which fewer than 10 percent are Beetles. Dies weighing up to 50 tonnes press into metal with 7,700 tonnes of force to stamp out body panels; on-site suppliers tag-in chasses to be married with drivetrains; and after being screwed together tight and electrostatically painted, a new car (or, increasingly, SUV) rolls off the line roughly every 90 seconds.

Getting It Right

Merely following an exhaustively detailed set of steps isn’t enough to declare a vehicle ready for the road. Despite the 90,000 hours of training that Volkswagen typically invests in its staff in preparation for a new model’s production, it’s still necessary for each and every one of the automobiles produced in Puebla to undergo a series of real-world tests so that it may be signed off as fit for sale.

I accompanied one of VW’s engineers – part of a 126-member strong, three-shift crew – who spends his days, and occasionally nights, putting a new Beetle through its paces. The model I rode in was, appropriately enough, a Wolfsburg Edition convertible slated for Canadian roads. We bumped down a suspension stress course, conducted emergency stops in both forward gear and reverse, watched the car track straight and true at 120 km/h with no hands on the wheel, and then interacted with as many buttons, toggles, dials, and switches as were visible before performing a detailed visual inspection of the entire exterior, including the hidden lands under the hood and inside the trunk.

It was a thorough, if surprisingly informal process, backed up by an officially stamped checklist, one that would later be followed by a “water penetration test” that sounded both wet and rather clinical.

Family Reunion

Dovetailing into the history of the original Beetle, the current model (née New Beetle) has been putting food on tables in Puebla since 1997. As our tour wound down and I gracefully exited the unique three-row, roofless Golf that had served as my transportation from one end of the factory to the other by leaping over the fender, I couldn’t help but notice the altar that had been prepared with offerings for Día de Muertos just inside of the Puebla facility gates.

It made me wonder if at next year’s festivities, with the Beetle firmly in the rear-view mirror and the Tiguan now leading the charge, whether the thousands who had drawn their livelihood from one of VW’s most celebrated designs would see fit to save a not-so-small corner of the spread for the hump-backed coupe and free-spirited convertible themselves. It would be a fitting tribute for a car so woven into the fabric of the Puebla community to find itself equally bound once it had passed, for the second time, into the memories of those who built it.