Volvo is serious about becoming a carbon-neutral automaker by 2040. A large part of that objective hinges on the company’s aggressive plan to introduce one new fully electric car per year until 2030, by which time it will sell only EVs. It’s a noble goal, and there’s much more to this complex equation than zero tailpipe emissions.

We spoke with Henrik Green, head of Global Advanced Technology and Sustainability, following the reveal of the upcoming 2024 Volvo EX90 electric flagship SUV in Stockholm. He outlined the myriad challenges and how the Swedish automaker is facing them.

Green says the most important pillar of this directive is recycling, and there are two aspects to this: 1) the recycling of used EV batteries, and 2) getting as much recycled material back into the new vehicles, be that steel, aluminum, or plastics.

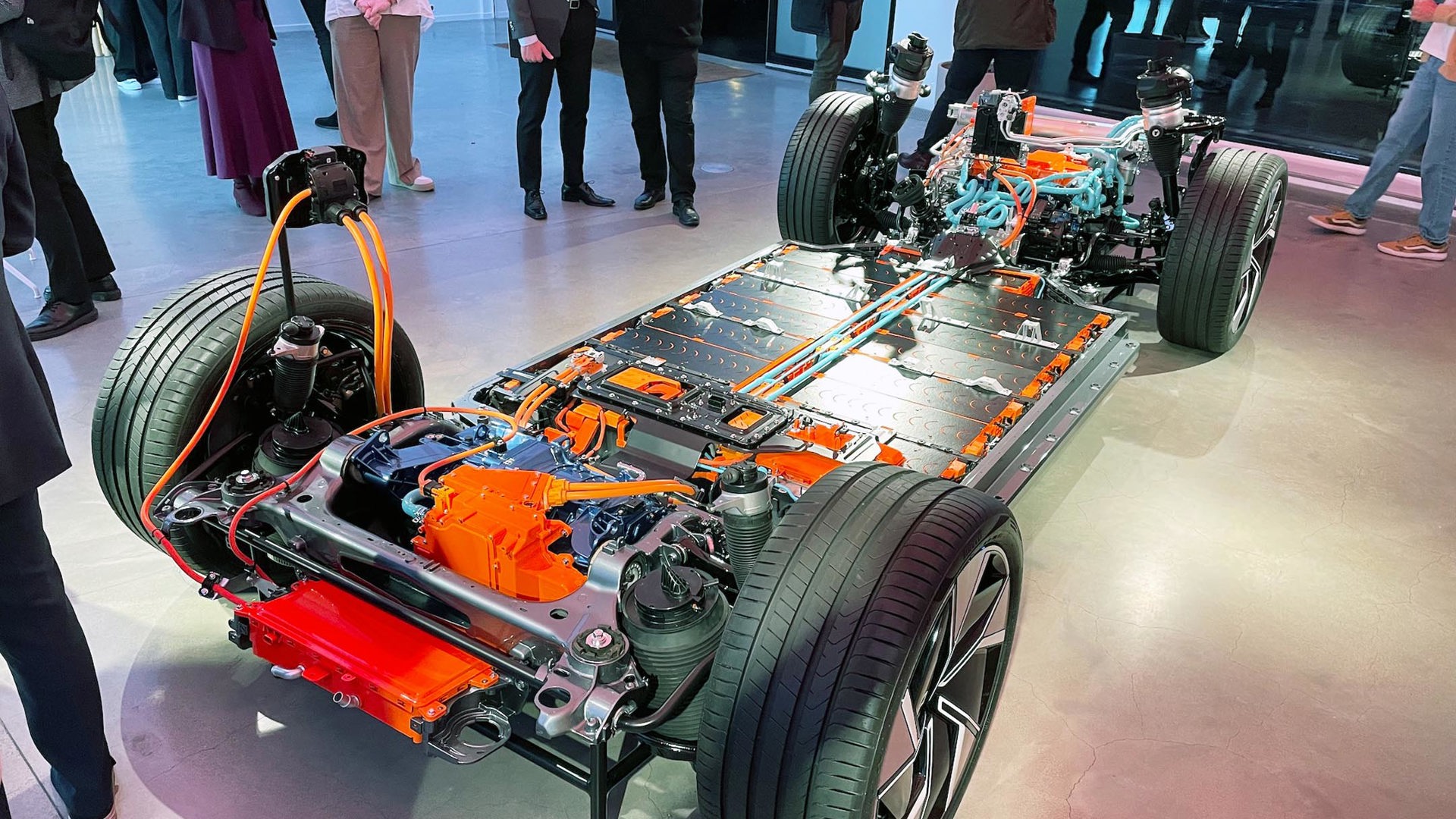

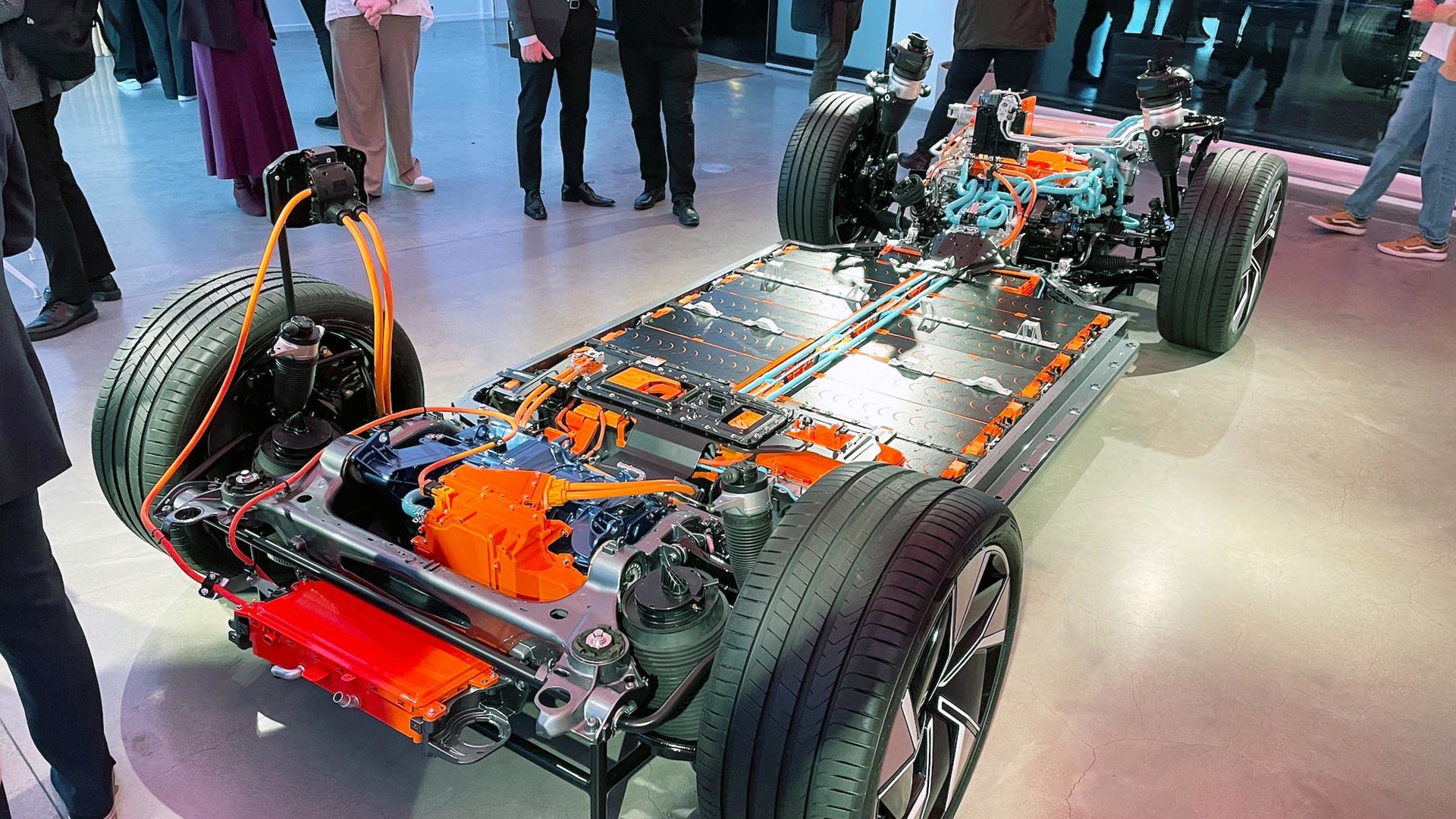

The battery represents the largest individual cost component in an electric car, as well as a major part of its carbon footprint. “A few years in the future, the battery won’t necessarily be virgin material, but it will come from recycled material, and we can start to get circular on that process,” Green says.

But he notes there is a built-in time lag for this, as the crop of batteries powering the current wave of EVs hitting the market won’t be retired for eight to 10 years. “That’s when we can massively recycle, but that’s probably a couple of generations of vehicles from now.” And yes, there will be a need for a large industry devoted to car battery recycling, which Green predicts will emerge as more and more EV batteries reach the end of their lives.

Volvo is partnering with Northvolt, a leader in sustainable battery technology, and is building a giga factory and R&D centre in Gothenburg, Sweden. As one of the largest cell production units in Europe, it will be powered by fossil fuel-free energy. Javier Varela, head of Engineering and Operations at Volvo Cars says, “Through our partnership with Northvolt we will also benefit greatly from an end-to-end battery value chain, from raw material to complete car, ensuring optimal integration in our cars.” The R&D centre will focus on battery recycling technology as well.

Transparency regarding the sourcing of minerals for batteries is important to Volvo. It presently traces its sources of cobalt, lithium, and nickel, with an eye on ethical mining and environmental awareness. This is an area where again, recycling could have a big impact, as the mining of these metals is arguably the most environmentally problematic aspect of EV mobility.

What about second or third life for a battery, wherein the pack is not recycled but repurposed? Green speaks to the future of home energy management. “With the EX90, we’ve launched bi-directional charging. You can charge your car and then discharge it and use it for your home. If you do that in combination with solar panels and home battery (used EV battery) you can drastically reduce consumption costs, be self-sustaining, and mitigate the risk during a power outage,” he said. “I would say in a number of years, the second life of EV batteries will compete with recycling. It’s a really interesting area where home batteries play a role, but on the other hand, we will be searching for old batteries as fast as possible to get recycling into the loop.”

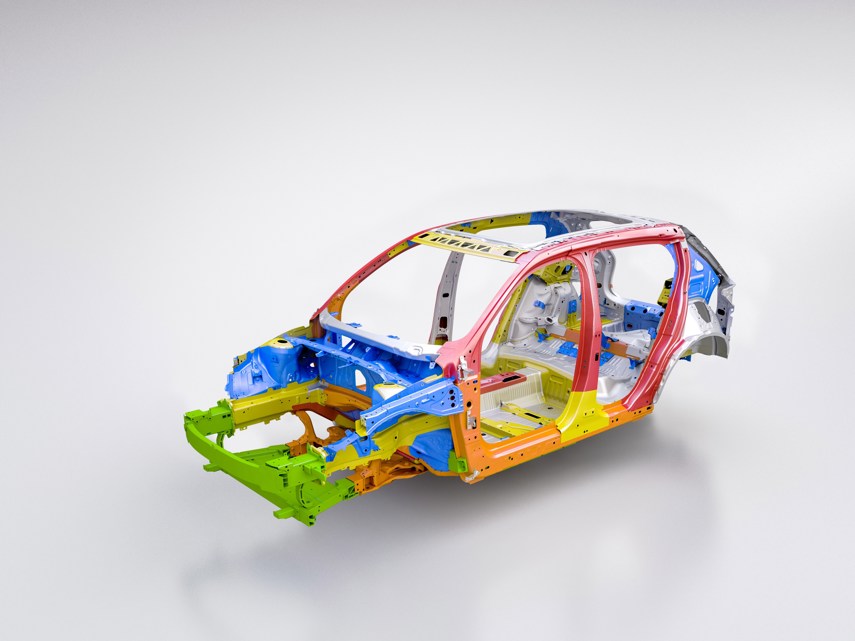

The three-row EX90 SUV launching in late 2023 contains the most recycled materials of any Volvo so far – 15 per cent of the plastics, 15 per cent of the steel, and 25 per cent of the aluminum is recycled. Of course, sourcing and processing these materials is expensive, but other limiting factors exist in making a car from recycled material.

“The further difficulty is to separate the parts. If we want to be real circular, we want not only generic recycling, but we want our cars to come back into the loop. I foresee in the long term we will engineer cars that are easier to disassemble and sort them in pure material boxes,” Green says.

Volvo will also expand its use of bio-based plastics. The EX90 has about four kilograms of the eco-friendly material.

With regards to the factory in the U.S. where the EX90 will be built for the North American market, the production line is running on climate neutral energy, and Green says they are working on other aspects like the heating of the building. “But the next step is the supply chain, and that is where we are actually working the hardest. How can we get the tier one supply, tier two supply, and tier three supply to also run completely on climate neutral electricity?” he asks. It’s a question that not long ago was answered in blank stares. “We have taken quick aggressive stances on reduction, and suppliers are coming around.”

A large part of Volvo’s eco-friendly push is driven by the interior design department. You won’t find any leather in the Volvo electric cars – methane-producing bovines are an environmental travesty. You will, however, see stylish wool blends, a convincing faux leather called Nordico, and materials made from recycled plastic bottles.

“With the pace of improvement that is needed, we can’t wait for a seven-year lifecycle of a vehicle,” Green says. “Although not yet official, I think that within those seven years we will increase the level of recycled aluminum and steel in order to reach our goal of being climate neutral by 2040.”