French sports car builder Alpine has just announced that its latest electric concept car has body panels made from linen instead of carbon fibre. The material is more sustainable and lower-impact than carbon panels, and allows for lighter assemblies. But Alpine is hardly the only automaker seeking out innovative new materials that are both more eco-friendly and better-performing than what they’re replacing. These types of innovations are popping up all over the auto industry and is equal parts exciting and cool. Here are some of the innovative automotive materials to look forward to. Some of them are already in production and others are close to being used in cars we should be able to buy one day.

Linen

Having a low weight is a crucial part of the Alpine A110 sports car, and Alpine wanted to preserve that trait when it built an electric concept car. Batteries made the car 258 kg heavier than its gas-powered equivalent, so two researchers came up with the idea of linen to save weight.

The linen fabric is sourced from Terre de Lin, a cooperative that has its home near Alpine HQ in Dieppe, France. Terre de Lin grows the flax that is processed and turned into yarn, which is then woven into a fabric made of 95 per cent linen and 5 per cent cotton. The fabric is infused with resin and placed in a mold like a traditional carbon-fibre part would be.

The linen panel by itself is about 20 per cent heavier than the equivalent in raw carbon fibre and 25 per cent lighter than aluminum, Alpine said. Because a linen panel has better acoustic properties and a few other benefits the company wasn’t ready to spell out just yet, the overall number of needed parts goes down, and that allows a greater weight saving for the entire assembly. If Alpine can find bio-sourced resins, which it is researching, then the panel can be completely decarbonized.

Cactus

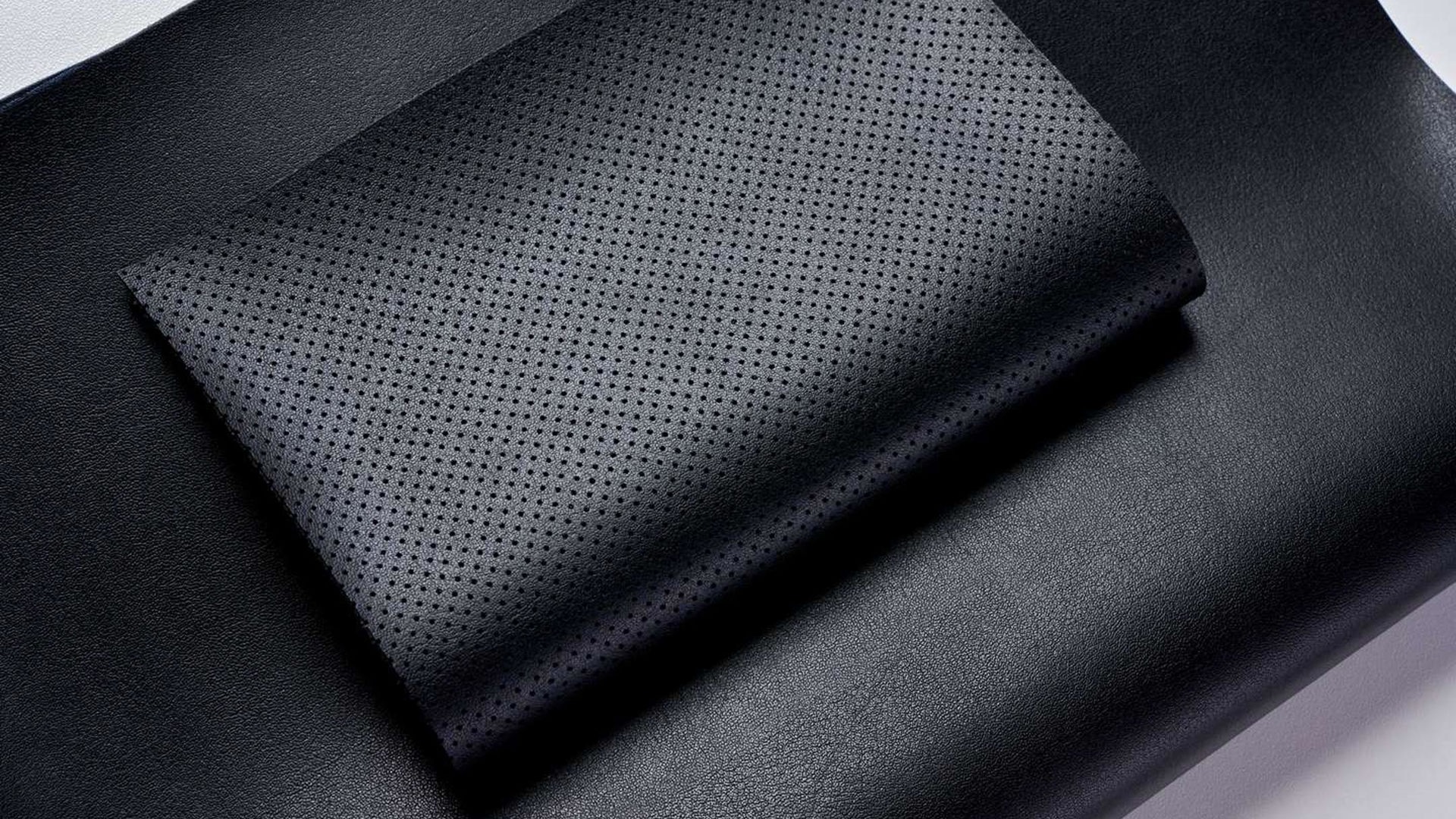

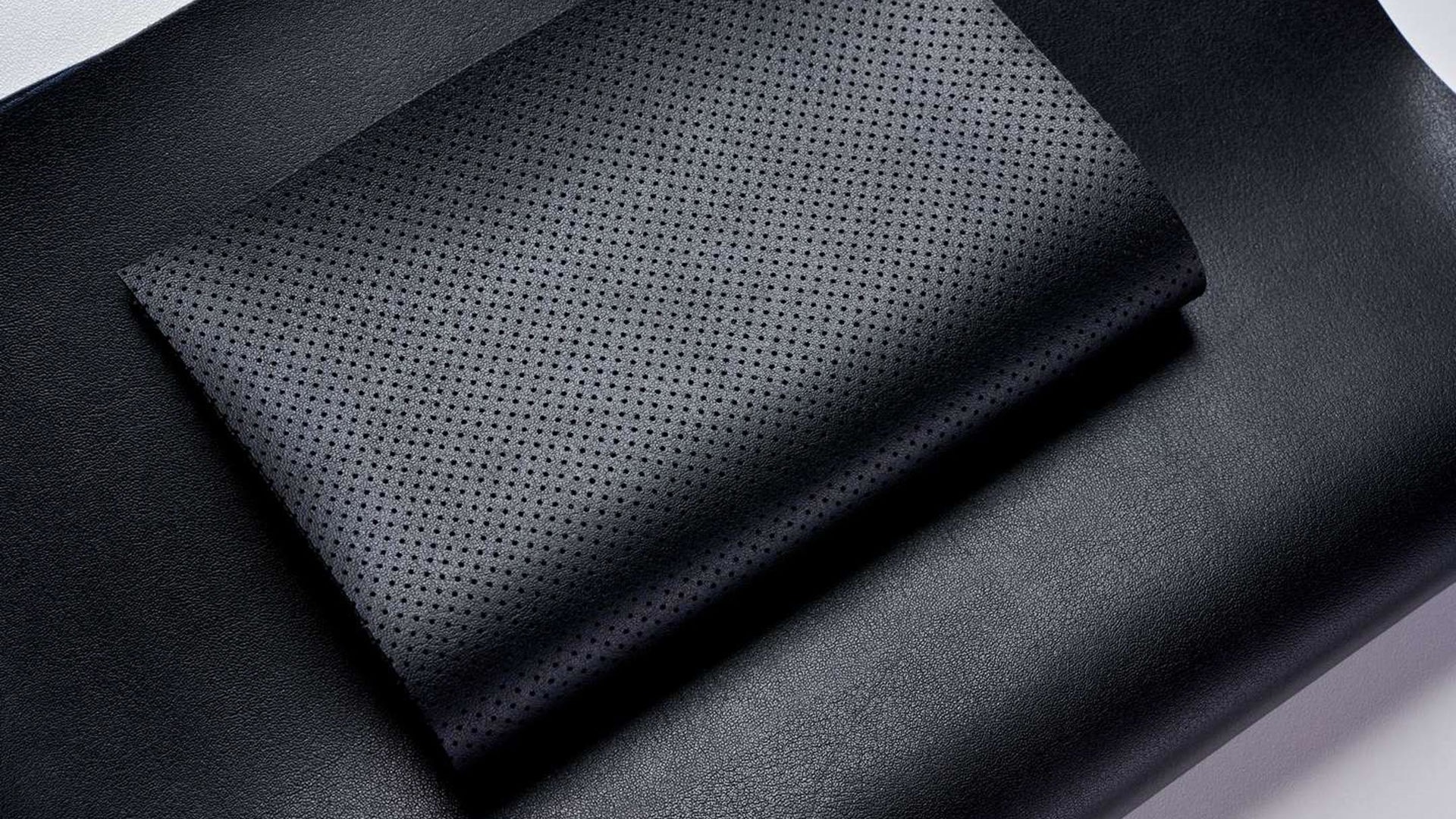

Mercedes-Benz and BMW have both announced plans to use a material called Deserttex in their vehicles in place of traditional hide or oil-based faux leathers. Deserttex is made by Adriano di Marti and is related to its Desserto leather used in the fashion industry. (Note: Yes, that is two esses in Desserto)

Deserttex comes from the prickly pear cactus. Only mature leaves are harvested, leaving the plant intact and allowing a harvest twice a year. The cactus plants don’t need irrigation, which further improves sustainability. The leaves are sun-dried and then processed with what BMW calls a “bio-based polyurethane matrix.” Deserttex is soft and “has a degree of roundness and spring,” di Marti says, which it likens to the behaviour and durability of animal-based leathers. The material helps automakers replace a product that is highly contentious for its atmospheric and carbon footprint and use of harmful chemicals with one that is carbon neutral and uses more eco-friendly chemicals.

Cork

Mazda was one of the first automakers to use sustainable and durable cork, because it was a link to where the company started. Mazda began life as Toyo Cork Kogyo before Jujiro Matsuda moved it into manufacturing machinery and then vehicles beginning in the late 1920s.

That history worked well with the sustainability of the product and is why Mazda used cork as trim in the MX-30. The soft and durable material covers the trim around the centre console and cup holders. That cork comes from the bark of trees (which doesn’t kill the trees) as well as from wine industry leftovers.

Volvo is also using cork, but in combination with pine oils and other bio-sourced materials from forests in Sweden and recycled plastic bottles. The ingredients, which include cork recycled from the wine industry, are turned into a leather-like material called Nordico, which Volvo says will get softer with use like the highest-quality hides rather than feeling like a recycled material or typical vinyl. Volvo says Nordico has a carbon footprint 74 per cent lower than leather and 27 per cent lower than standard vinyl.

Fishing Nets

Ghost nets is the term for fishing nets that have been abandoned, lost, or disposed of in the ocean. Around 48,000 tons are reportedly dumped in the water every year, and the result is horrific for ocean life. Econyl is a recycled nylon product that is made entirely from ocean and landfill waste, giving fishers a reason to bring their nets back rather than leave them at the bottom of the ocean. The other main material used in Econyl is old carpet, allowing discarded floor coverings to be recycled and reused.

Using high temperatures and steam instead of more chemical agents, Econyl turns the old nylon into fresh new material. Volvo first used this material in a car in 2018 and the Polestar 3 uses 100 per cent Econyl for its carpets. BMW uses the material, which reduces manufacturing carbon emissions by 90 per cent, in the headliner and carpets of the i3, iX, and other models. When the vehicle reaches end of life, Econyl fabrics can be recycled again to be used in new vehicles.

Soybeans

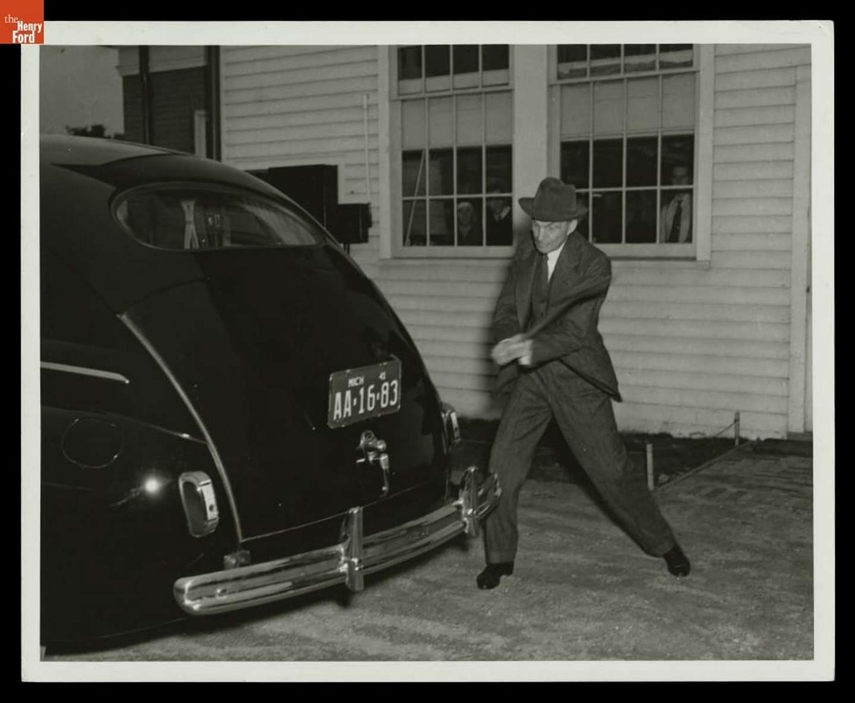

Henry Ford started using soybeans in Ford cars back in the days of the Model T. At one point, the T had around 30 kilograms of soybeans in its paintwork and plastic parts, with Ford increasing that use into the 1930s. In 1941, he unveiled a car with body panels made from a soybean-based composite material, though it was derailed by the war.

Today, Ford has been using soybean-based foam in the seat cushions, backrests, and headrests of every vehicle it makes in North America for more than a decade. And while many of the soybean-based foams used in other industries (soybean mattress foam is growing increasingly popular) where soybean is a tiny fraction of the content, Ford’s formula replaces almost half of the oil-based foam with soybean products. Ford says that it has saved hundreds of millions of kilograms of carbon dioxide from entering the atmosphere thanks to this foam, and it is working to make parts like rubber gaskets and even windshield wiper blades from the crop.

Dandelions

That weed you’re trying to get rid of in your lawn might soon make for more environmentally friendly tires. Right now, up to 30 per cent of a car tire (and around half of a truck tire) is made from natural rubber. While natural rubber used to be seen as sustainable, rubber trees can only be grown in a small and shrinking part of the world. The trees take seven years to grow before they can be tapped for latex, and demand is quickly increasing.

Continental Tire has found a specific species of dandelion that also has natural rubber latex in its roots. The crop can grow in a much wider climate, grows more quickly, and is less sensitive to weather. Continental calls the dandelion tires Taraxagum and started on-road testing in 2014. The tire company is already producing bicycle tires using the material and says it is hoping to make car and truck tires from dandelions in the next five to 10 years.

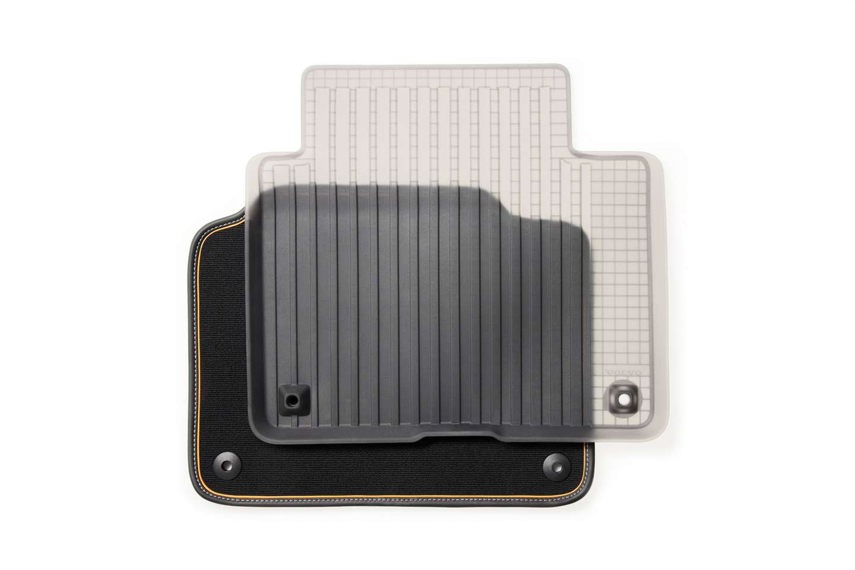

Ford has also experimented with dandelions in cars. It used the same species as Continental to get rubber for use in floor mats as well as cup holders and other interior trim pieces.

Coffee

Back in 2019, Ford announced a partnership with McDonald’s that gave us a morning buzz. The plan was to use coffee chaff, a waste product of coffee bean roasting, to help make car parts like headlights. The coffee chaff composite (it’s mixed with some traditional plastic) material resulted in headlight housings and some other components that were 20 per cent lighter and performed better in some areas than pure petroleum parts. The coffee-based parts also took 25 per cent less energy to mold, making for a serious win when it came to cutting the environmental footprint of the material. Ford started installing these lights in the Lincoln Continental in 2019 and the coffee lights are now found in multiple Ford vehicles.

Cash

This one doesn’t seem to have made it beyond the prototype stage, but it was just too cool to leave off the list. Ford worked with the U.S. Federal Reserve, which is responsible for destroying worn-out banknotes. Millions of kilograms of worn-out cash are shredded and then either burned or dumped in a landfill. Instead of tossing it, Ford took advantage of the long fibres found in the cotton and linen used in the bills and combined the material into a plastic composite. The prototype parts included various plastic trim bits, but the highlight was a coin holder to go into a Lincoln MKX centre console, which seems extremely appropriate.