You might not give much thought to the plastic bottle or cardboard box you throw into the recycling bin, but someone does. The next time you buy a car, you just might be buying your trash back.

Cars have always been recycled, but in the past it was primarily for their metal. Now, not only is more of each vehicle being recaptured, but more recycled material is going into new ones. And some of what’s being used will surprise you – right up to clothing and food. Here’s a rundown on some of what’s being made “old into new.”

Metal

Virtually all the metal in a scrapped vehicle is sorted for recycling into new material, much of which goes back into the auto industry. Aluminum is especially valuable and can be recycled over and over. Honda uses old aluminum engine blocks to make new frame components, while Jaguar uses leftover aluminum from the factory, along with post-consumer metal such as discarded aluminum rims, to turn into new vehicles.

It isn’t just from junked cars, either. There’s always some waste when body panels are stamped, such as the window openings punched out of doors. Ford estimates it collects and recycles some 2.2 million kilograms of this leftover metal each week between three of its factories. As well, some automakers have recycling initiatives to collect other metals, such as nickel from batteries, or platinum from catalytic converters.

Bumpers

Scraped and dinged in parking lots and fender-benders, plastic fasciae frequently end up as scrap at body shops. Mazda says it was the first automaker to find a way to strip the paint off them, chop them up, and melt and mould them back into new bumpers. Several automakers now do this.

During production, fasciae that come out of the mould with blemishes are often taken directly to a section of the plant, such as at Subaru’s factory in Indiana, where they’re chopped up and sent back over to make new bumpers in a “closed-loop” recycling process.

In addition to being made into new bumpers, old ones are also turned into splash guards at Honda; into the spare tire well at Audi; and Hyundai is experimenting with using bumper plastic for headlamp housings and door trim.

Food

There might be food in your new car, and not just what you got at the drive-through. In addition to milk and meat, coconuts produce coir, the rough hairy stuff on the outside of the nut. Most of this goes to agriculture, but some automakers get their hands on it too: Ford uses it as an ingredient in trunk mats.

When soybean pulp is left after making tofu or soy milk, companies like Kia, GM, and Ford use it to make seat foam. Ford uses wheat straw or rice hulls to reinforce various plastics instead of glass fibres, and Toyota uses sugar cane in some of its bioplastic parts.

But the oddest has to be – wait for it – olive pits. Mercedes-Benz uses activated charcoal, made from burned olive stones, in the fuel tank ventilation filter in its S-Class.

Plastic Bottles

There are likely a more than a few water or soda bottles made from PET (polyethylene terephthalate) in your new vehicle. They’re spun into fibres and used to make seat fabric – Ford estimates as many as 110 bottles go into an F-150’s seats – and carpet, such as in the Nissan Leaf.

General Motors collects water bottles discarded by employees at its factories and offices, and turns them into hood insulation panels (extra fleece fabric made from the bottles is donated to charities to sew into coats). A few automakers, including Nissan, make plastic parts from polypropylene bottle caps.

Other Plastics

It can be difficult to recycle some plastic because it’s a blend of different types. Some automakers, such as Mercedes-Benz, are trying to use a single type in each application where possible, so it’s easier to recycle the vehicle at the end of its life.

Plastic caps are often used to protect parts when they’re shipped to the factories. Among others, General Motors collects these and turns them into radiator shrouds for its pickup trucks.

At its Japanese factories, Nissan uses plastics collected from electrical appliances, such as refrigerators and stoves, to turn into auto parts.

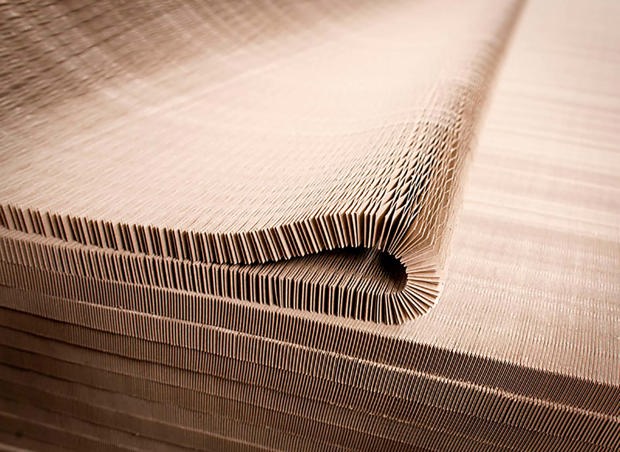

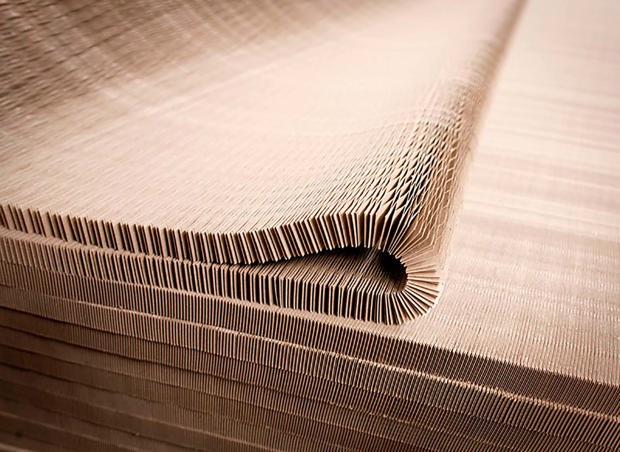

Cardboard and Paper

This shows up in a few vehicles. Audi uses recycled cardboard as a layer in its cargo floor, while Ford’s new Ecosport has a honeycomb layer of recycled cardboard to stiffen its cargo shelf. Buick uses it as an ingredient in sound-deadening insulation.

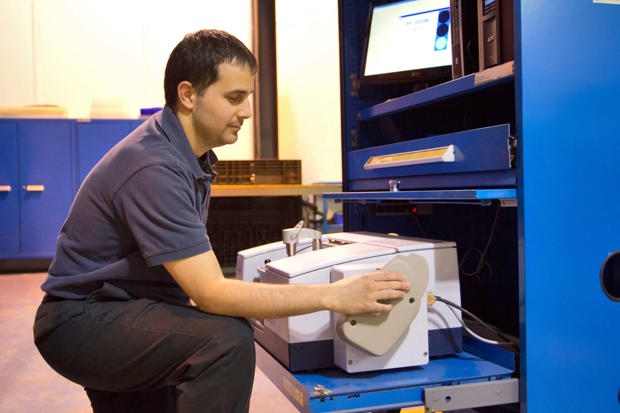

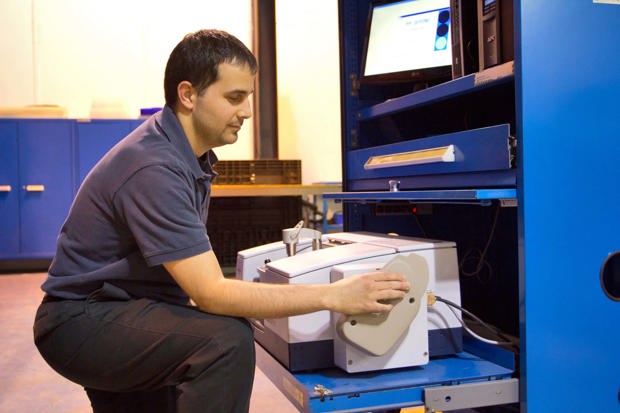

Carbon Fibre

Carbon fibre is difficult and expensive to recycle but BMW works with it, both in end-of-life vehicles and during the production process. Hardened carbon fibre is chopped up, heated, and mixed with new material to make synthetic fabrics. During vehicle production, carbon fibre sheets are cut to fit before they’re hardened with resin to make parts. The trimmings, known as offcuts, are used to make fleece roof mats and console backing for the i3 and i8.

Clothes

Cotton has a second life after T-shirts and jeans, and most of it ends up in sound-deadening insulation. Nylon can also be recycled, and the fan shroud in Jeep’s Cherokee contains some of it. Ford, meanwhile, takes nylon carpet and turns it into engine head covers on its F-150 and Mustang, among other models.

Rubber

Tires have a recycling stream all their own, and almost all tires collected – most of them under provincial stewardship programs – are turned into new products (it used to be common to burn most of them in cement kilns, but that’s not the case anymore). Much of this rubber goes outside the auto industry, such as playground surfaces and industrial mats, but your old tires could still end up in your new car. Automakers such as Kia, GM and Ford use recycled rubber to make seals and gaskets. Meanwhile, the steel wire in the tire bead is captured and recycled into new metal.

Seat Foam

Chrysler collects polyurethane foam from discarded seats and recycles it into new plastic that’s used in the Jeep Grand Cherokee’s seats.

Remanufactured Parts

Of course, from an environmental and cost standpoint, the best recycled part is one that doesn’t need much recycling at all. Many failed parts can be rebuilt, including engines, transmissions, starters, alternators, and power steering pumps. Commonly known as “reman,” they’re generally not used in new-car production, but are sold by dealerships and auto parts stores for repairing vehicles. You usually pay a deposit, called a core charge, which you get back when you bring in your old part – and that part goes straight to the remanufacturing facility.

And then there’s the weird stuff…

Automakers and other industries are always working on new and better ways to recycle materials, and also how to use them. It’s actually a long process, since any new material has to be thoroughly tested to be sure it’s going to work, and that it can be reliably produced in sufficient quantities.

Among some of the odder recycling stories, Subaru sends burned-out light bulbs to a company that uses them in road reflectors. Honda makes a type of polyester using fermented corn.

And while it’s all still in the experimental stage, Ford is looking at turning cold hard cash – actual US currency that the government has taken out of circulation and shredded – into reinforced plastic; and dried tomato skins, leftover from food processing, in its wiring brackets. It’s even working with Jose Cuervo to see if agave, once it’s given up its goodness for tequila, can be made into bioplastic. Lime and salt with your car, anyone?