Suspension: to the average driver, it’s a collection of springy things underneath your vehicle that makes it ride the way it rides. The closest most folks have ever been to a shock absorber or strut has been in the Canadian Tire flyer on Thursday evening—but today, we’re going to change that, with our Illustrated Guide to Suspension!

After reading and browsing through the photos below, you’ll understand the basics of suspension components, popular suspension system anatomies, some high-tech advances in the world of suspension, and what happens when your suspension wears out and needs maintenance.

There’s a complicated elastokinematic (that means springy things that move) orchestra of parts and pieces at work beneath your ride, just waiting to be discovered. Let’s jump in.

The Basics

Springs

Springs store energy created when your ride whacks a monster pothole or road-crater driving down the street. Springs compress and rebound, absorbing and storing the energy of a bump in the road, and releasing it slowly, to prevent the energy of a bump from going straight up your spine. Springs can come in all shapes and sizes, calibrated to create precise characteristics related to ride height, ride quality and handling. Thing is, once set in motion by a bump, springs want to keep doing their spring-thing and bounce all over the place like a kangaroo who just drank a case of Red Bull. This is called oscillation, and left unchecked, it would screw up your ride’s handling and make you sea-sick and barfy.

Shocks

In many a ride, shocks work in sync with springs within the suspension system. These two common components deliver the bounce, rebound and damping characteristics set by the folks who engineered your ride, and are largely responsible for the way it goes down the road. Importantly, shocks also mitigate the tendency of your springs to keep your ride bouncing down the road after a bump is encountered, by regulating how quickly the energy in the spring is released.

Does your ride float over speed bumps like its shocks are made of fluffy clouds, or does it bounce tightly and help punch corners square in the face with sporty handling? Does your machine absorb and neutralize bumps, or crash into them? In any case, shocks are largely responsible for the way your ride rides.

Does your car hit a bump on the highway and keep bouncing for a half minute afterwards? If so, it probably has busted shocks, which aren’t properly regulating the oscillation of the springs. See your mechanic.

But what’s a strut?

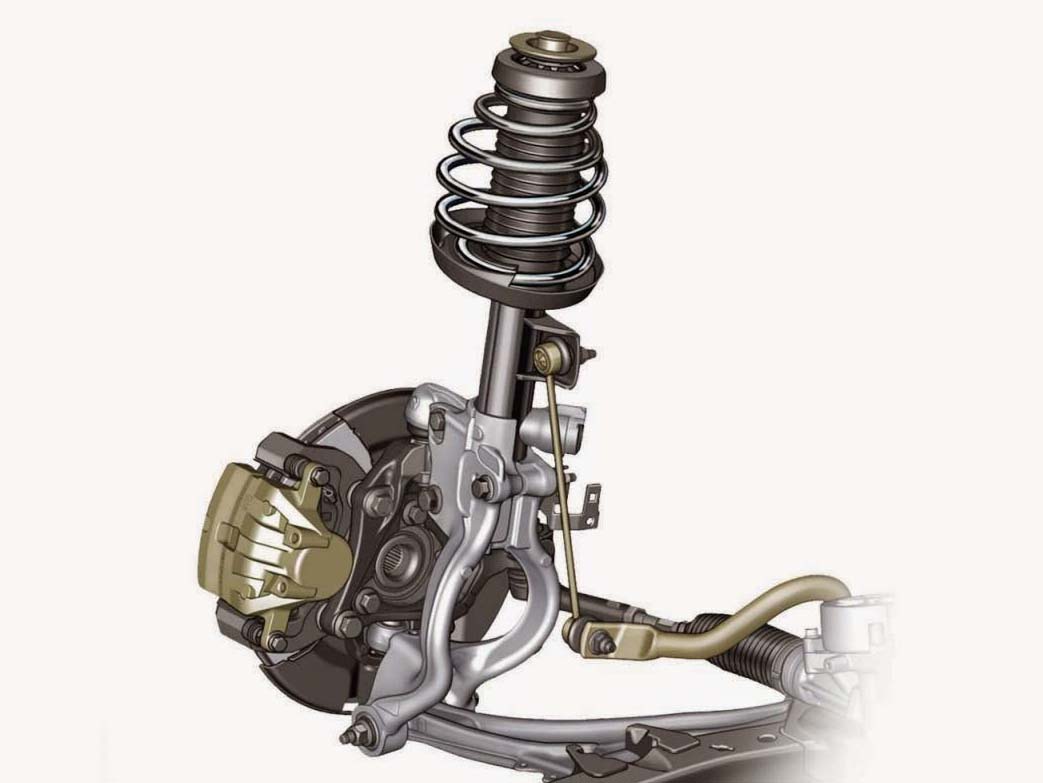

The words ‘shock’ and ‘strut’ are sometimes used interchangeably, confusing and discombobulating the average driver. What’s the difference between a shock and a strut? Simple: a shock is just a shock. A strut is like a shock, but with the spring and other suspension components integrated. In some vehicles, the shocks and springs are separate from one another. In other vehicles, they’re combined to form a single strut, creating a more compact suspension system. In the picture above, notice that the spring has the shock mounted through its centre as a single unit, thereby creating a strut.

Ball Joints

Giving these rigid suspension parts flexibility where they’re attached to one another is the responsibility of the ball-joint. A ball joint allows fixed suspension parts to be joined together in a way that lets them move and twist in relation to one another, as needed. In this picture, we see naked ball joints—with the physical joint concealed inside of a housing.

Note the little nipples, which allow lubricating grease to be added as part of vehicle maintenance, to keep the ball joints moving freely. When ball joints wear out, they typically make a loud banging noise as the vehicle is driven over bumps. If they fail, your car could lose a wheel, possibly with suspension components attached to it, which is not fun.

Control Arms

In some vehicles, the control arm connects your vehicle’s chassis or frame to the components that carry the wheel. Sometimes called an A-arm, this important part of a suspension system houses the wheel hub (which holds the wheel), and is acted upon by a shock or strut, which controls and regulates its motion up and down over bumps in the road. The control arm is mounted to the structure of the vehicle on pivots that allow it to move. They’re the middle-man between your wheel and your ride, and are connected to your shocks, springs and/or struts. In this photo, the light-silver component is the Control Arm, and the spring-loaded strut can be seen passing through it. BONUS: look closely, and at the outer tip of the ‘A’, you’ll see a ball joint, complete with characteristic grease-nipple on top.

Sway Bars

Here are some naked sway bars that fit on a Dodge Challenger. A sway bar is simply a metal rod that connects the front wheels to each other. Sometimes called a stabilizer bar, this important component is bolted, at either end, to the front suspension, and also anchored, in the middle, to the vehicle’s body structure. Go around a corner, and the compression of the suspension applies torsion, or a twisting force, to the bar, which is transmitted across the front suspension to the other side, reducing the tendency for the body to lean or roll. Simply, connecting both sides of the suspension to one another via a fixed sway bar helps use the mechanical cornering force exerted on the suspension on one side of the vehicle to compress the suspension on the other—enabling flatter cornering.

Sway Bars Continued

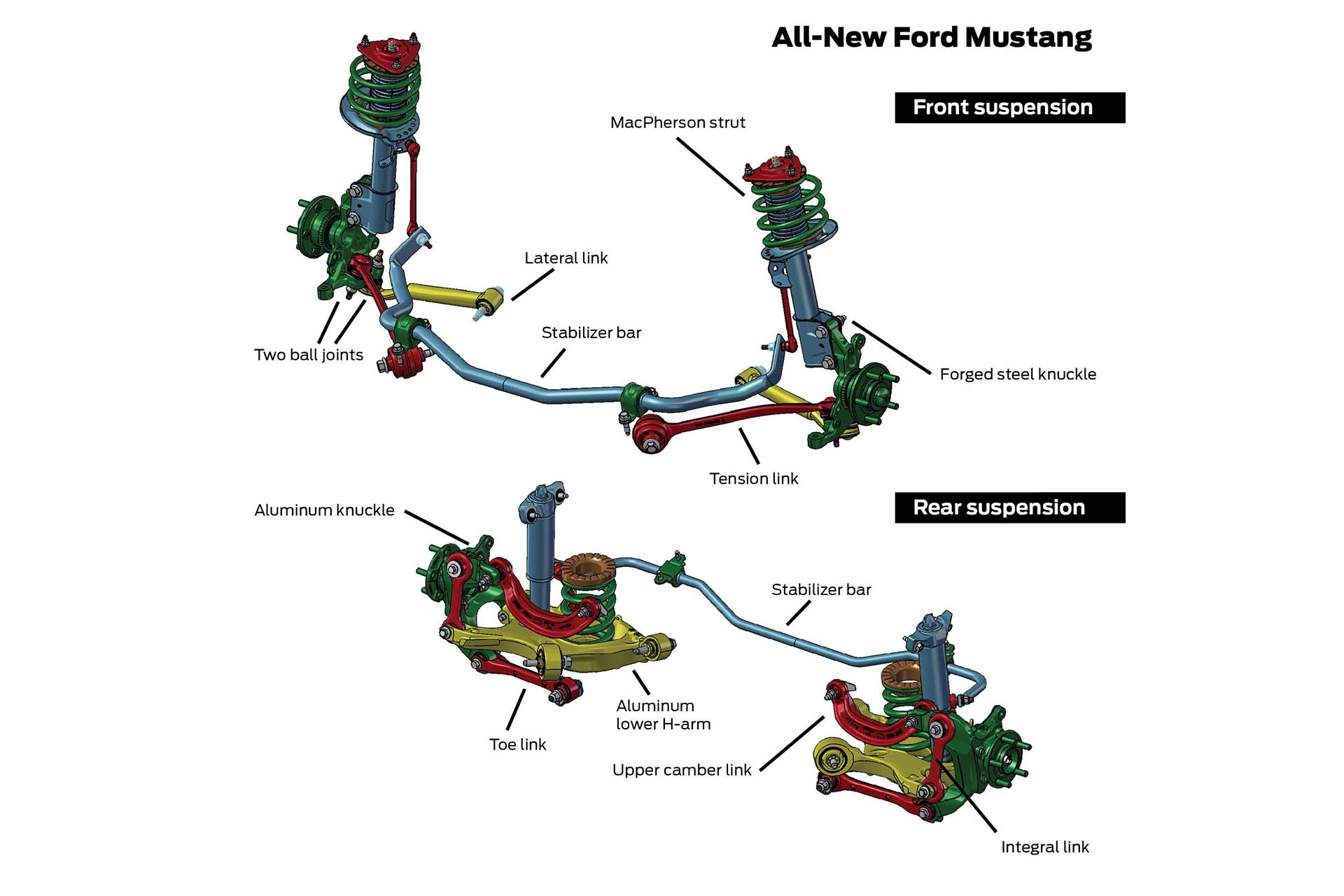

Sway bars are typically attached to the front control arms by a little doodad called an end link. Knocking sounds and sensations from your front end, as well as sloppy handling and steering feel can be signs that your end links need replacing. Here’s a picture of how Ford applies the sway bar, or stabilizer bar, to the suspension of the new Mustang. BONUS: look closely at either end of the sway bar in the Front Suspension diagram, and you’ll see a thin red vertical rod, which is the end link that connects the sway bar to the front strut. When these little suckers wear out, they’ll often make a tapping or rapping noise, and your car will start to handle like soggy toast. See your mechanic.

Bushings

Bushings come in all different shapes and sizes. Some are like little rubber donuts or tubes, and all are used to mitigate the noise and vibration inherent when metal suspension components are bolted to other metal parts. By using rubber bushings to isolate and prevent metal-on-metal contact between components, suspension noise, harshness, wear and other ill effects are eliminated. Since they’re typically made of rubber or polyurethane, bushings can be manufactured with a certain viscosity, which affects ride and handling characteristics. Your car has dozens of bushings beneath it, all helping keep suspension parts from banging into one another, while cushioning and quieting the workings of the various components. Bushings are sort of like the rubber sole on your shoe, keeping your feet from actually touching the ground when your feet touch the ground. Pictured are a set of sway-bar bushings, which keep the metal sway bar from directly contacting the vehicle frame structure they’re attached to.

Suspension Anatomy

Double Wishbone

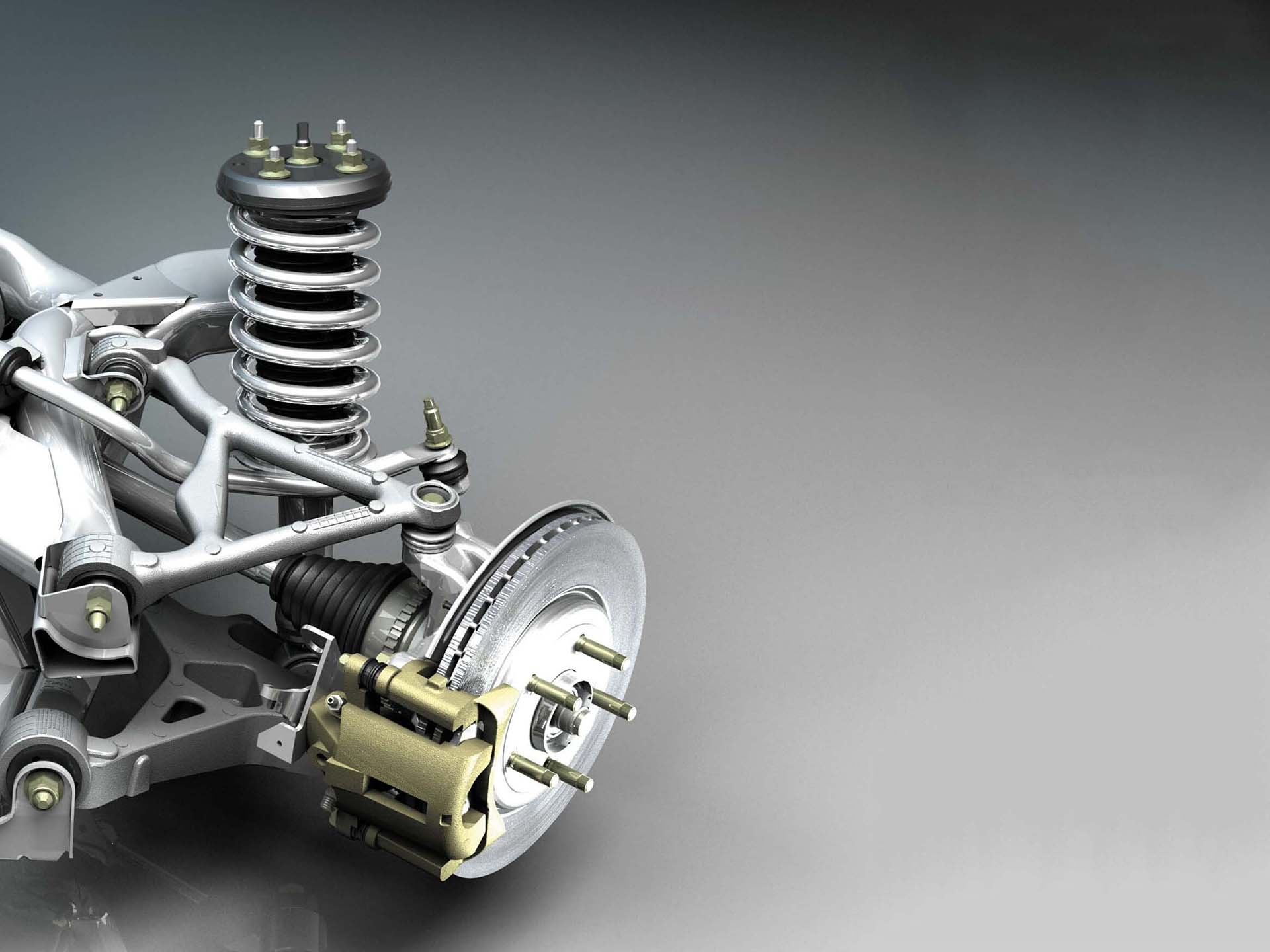

A favorite suspension type for car buffs and handling enthusiasts, double-wishbone suspension typically sees the wheels bolted to a hub fixed between two wishbone-shaped assemblies that mount to the vehicle’s structure. Double wishbone suspension is often found in performance cars, because of its rigidity and ability to maintain alignment characteristics under high g-force loads. Benefits include handling precision and high-speed agility, though the double-wishbone suspension is relatively more complicated, bulky and expensive. Here, we see one type of double-wishbone suspension. Do you see the wishbone (aka A-arm, aka control arm) on top, and the other hiding beneath? Of course you do, because you’re a champ. Look closely, and you’ll see a strut, ball joints and even bushings in this photo.

MacPherson

The compact and clever MacPherson strut suspension system centers around combining the spring and shock absorber into a single strut assembly—saving space, weight, complexity and cost. This popular type of suspension doesn’t need an upper control arm, meaning it’s more compact and can even improve interior volume. Drawbacks include some issues with handling in low-to-the-ground cars, and relatively limited handling capabilities compared to the double-wishbone design. We looked at a strut, or MacPherson strut, earlier, and here’s a picture of it as it relates to the rest of a suspension system. Look closely for the sway bar and end-link connected to the strut, too.

Torsion Beam

Primarily used as a space-saving rear suspension design in front-wheel drive cars, the Torsion Beam, or Twist Beam suspension is big on being economical. Two trailing arms, which connect the rear wheels to the vehicle’s body structure, are connected via a long piece of steel tube that acts like a spring. This suspension type is simple and cheap, and since it’s oriented horizontally, it takes up less space inside the vehicle, often enabling more trunk or cargo space. Part of the springing action, stabilizing and shock-absorbing capability is built into the long twist-beam, shown here in red.

Leaf spring

Springs aren’t always coiled. Example? Leaf springs. This type of simple and effective suspension is noted for cost and durability, and is common on pickup trucks. A leaf spring is a long and flat ‘blade’ of a special type of steel, with a slight bend or arc built in via the manufacturing process. Numerous blades, or steel springs, are typically stacked on top of one another, with special clamps holding all leafs in place. The springs deflect horizontally over bumps. By their design, leaf springs are well suited to various off-road applications, and handle heavy loads better than other suspension types, making them ideal for heavy-duty vehicles. Here, you can see the leaf springs, running the length of the vehicle, with the rear shocks mounted just inside of them.

Suspension High Tech

Electronic Sway Bar Disconnect

Remember sway bars from above? They tie the front suspension together from side to side to help enhance handling and control. Thing is, since sway bars limit the independence between the two front wheels, they can be pesky in severe off-road situations where maximum suspension flexibility and independence is needed. Some automakers offer a system to temporarily disconnect the sway-bars in off-road vehicles, allowing full suspension movement and flexibility for tackling obstacles. Below a certain speed, a simple button-press disconnects the front sway bars, enabling full suspension articulation for climbing steep obstacles. Many off-roady types install aftermarket sway-bar disconnections as well.

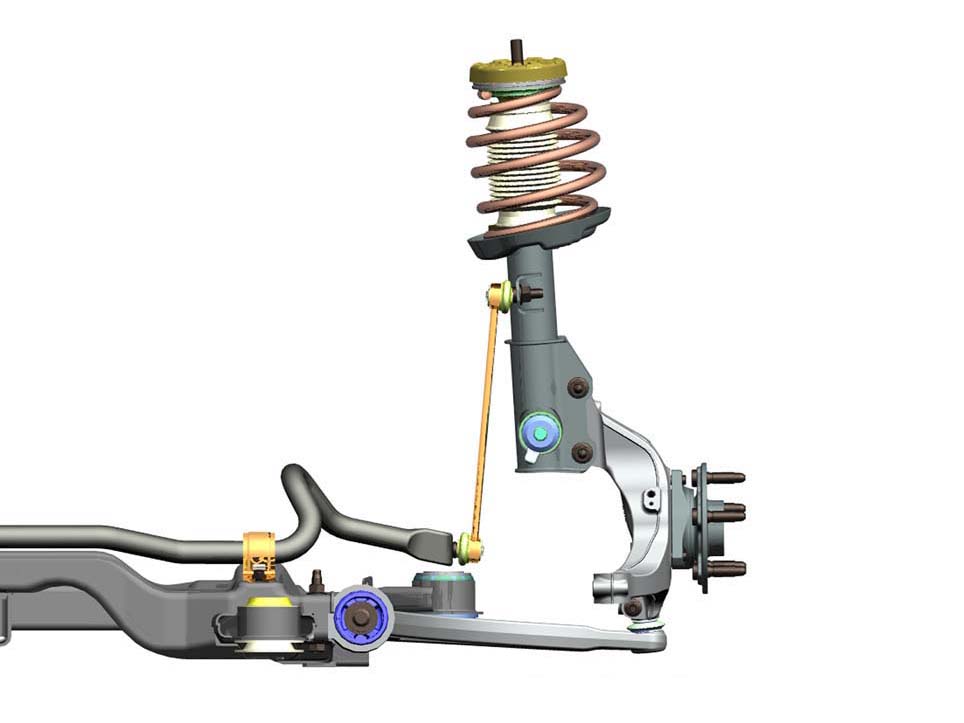

Above, you can see the sway bar (and end link) on one side of the suspension. But notice the metal assembly with a little blue writing on it? This component has both ends of a halved sway bar mounted inside. It can mechanically join the sway bar halves to function like a normal sway bar on the road, or separate the sway bar halves, allowing full flexibility in an off-road setting.

Magnetic Ride Control

Normally, shock absorbers are filled with oil and fitted with a special valve to create a set level of resistance to compressing and bouncing. As you travel over a bump, oil in the upper and lower parts of the shock absorber need to pass through the valve, with the opening in the valve, and the viscosity of the oil, playing a key role in the performance of the shock or strut.

GM has a revolutionary and high-tech take on this system, which uses a special type of oil filled with magnetic particles whose viscosity can be changed via the presence of a magnetic field. At the direction of numerous sensors, a small electromagnet on each damper actively changes the viscosity of the oil, and therefore, the characteristics of the damper, instantaneously and on-demand. Benefits of this Magnetic Ride Control system include real-time optimization of ride and handling characteristics, without compromising ride quality for agile handling.

Air Suspension

In some vehicles, the metal springs and struts are replaced by special thick rubber ‘bags’ full of air. The rubber chambers have a natural springiness built in, which can be altered by pumping air in and out of them. With air suspension, controlled by the amount of air contained within this thick rubber airbag, engineers can give drivers better ride quality, or even the ability to lift and lower their vehicle at the touch of a button. Case in point? This vehicle can be lifted up over its wheels for clearing obstacles, and lowers towards the ground at highway speeds automatically to help improve aerodynamics and save fuel. When parked, the suspension can be lowered even further, making it easy to load up gear, or your elderly grandmother.

Mercedes Magic Body Control

Imagine a suspension system that knew about bumps and holes in the road, before they were struck… The Magic Body Control system in some Mercedes models employ stereo cameras to scan the road ahead for obstacles like bumps and potholes—imaging the pavement defect with millimetre-precision in real time as the car moves down the road. Imaging data is sent to the adaptive suspension system, which is then pre-programmed with data relating to the upcoming bump or pothole. In effect, the suspension can pre-adapt itself just before striking an obstacle, which dramatically smooths out the ride. Magic!